During the transportation of the fuel tank truck, static electricity as an "invisible tinder", sometimes an inattention, will lead to unexpected dangerous accidents. So, how to prevent electrostatic hazards?

There is too little oil in the tank of the water tanker semi trailer, and there is a large shaking space during transportation, which is easy to generate static electricity; too much is installed, it is easy to cause overflow to the car with a tight seal at the tank mouth of the diesel tanker trailer, so the filling volume is about 85% As appropriate. In addition, medium speed should be maintained during transportation to ensure that the fuel in the tank of the tank truck is relatively stable, and emergency braking should be minimized.

60000 litres Aluminum fuel tank semi-trailer

The so-called change in oil loading refers to, for example, an oil tank that was originally filled with gasoline, and is now filled with kerosene or diesel oil, or vice versa. It is easy to form explosive mixed gas in the tank by changing the oil filling, especially if the original gasoline in the oil tank of the tank truck is now loaded with kerosene or diesel. The reason is that both kerosene and diesel have the property of absorbing gasoline vapor. It will make the oil tank that has been filled with gasoline vapor and reach the rich state, be diluted to the extent of explosion, especially in winter, if static electricity occurs Fire jumping means serious accidents such as fire and explosion may occur.

According to an accident investigation report from the American Petroleum Institute, of the 620 electrostatic accidents that occurred in the gasoline tanks, 440 were caused by changes in fuel loading. Therefore, when changing the fuel in the diesel tanker trailer, try to drain away the oil deposits in the tank, open the tank opening, and let the oil remaining in the tank volatilize as much as possible. In addition, the oil delivery personnel should be informed of the original oil contained in the oil tank when filling the oil, so that the oil delivery personnel can operate according to the regulations, such as limiting the flow rate of oil delivery.

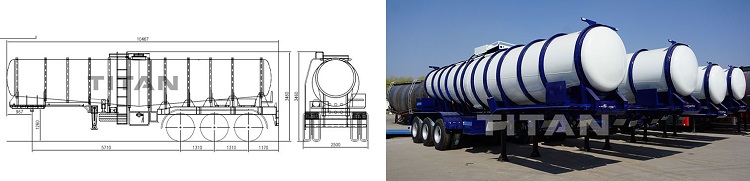

98% sulfuric acid tanker semi trailer

There must be no moisture, impurities, etc. in the fuel tank of the petroleum tanker trailers, because the water content in the fuel will significantly change the charging trend of the fuel, which will increase the voltage in the fuel tank by several tens or even hundreds of times, and may also be in the form of sparks Discharge.

The impurities in the oil also have a greater impact on the generation of static electricity, especially some floating substances, such as wood chips, rubber, and isolated metal balls (some floats on the oil tank content scale of some tank trucks) are very dangerous. The main reason is that this type of conductivity has a capacitive function to collect and store more electrostatic charges. There is no fixed moving track in the tank of the tank truck, and it is easy to access the tank wall or other accessories in the tank of the tank truck to form an appropriate discharge. gap. According to the test, once this phenomenon is formed, as long as the potential difference with the liquid level is 1-2KV, spark discharge may be generated (common liquid level is 28-30KV), and the discharge energy is strong, which can release all the stored energy at once.

The valves on the fuel tank, the exhalation valve, the sealing ring of the tank cap of the tanker, etc. should always be in good condition to prevent the fuel from leaking or overflowing, and to catch fire due to static electricity.

Monoblock tanker trailer for sale

Before loading and unloading the oil, the fuel tank truck and the oil loading and unloading equipment must be bridged together with static wires (the static wires that are connected to the tank truck are installed in the oil depot).

Function:

①Guide away the static electricity induced by the oil tank to avoid fire with external substances;

② Keep the tank truck and the entire loading and unloading equipment at equal potential to prevent potential difference;

③ It has the effect of accelerating the leakage of the charge in the oil. When connecting electrostatic wires, be sure to select non-corrosive and bare metal parts on the tank truck, and do not connect them to places with severe corrosion or paint.

The data shows that only when the resistance of the entire electrostatic grounding system is less than 10 ohms can good electrostatic conductivity be achieved. The ideal method is to install a special copper connection plate in a certain part of the tank truck, which is specially used to connect the electrostatic wires. In addition, the static ground wire on the tank truck cannot be used as the static wire for loading and unloading oil, because the tank truck is generally parked on cement or hard ground during loading and unloading of oil. The resistance of the static ground wire is not It may be less than 10 ohms. Therefore, it is difficult to ensure that the same loading and unloading equipment maintains the same potential.

4 axle oil fuel tank trailer

The anti-static facilities on the tank truck are mainly the static grounding wire and the oil separator in the tank. There are two types of static grounding wire: chain type and conductive rubber support. The former has shortcomings such as sparking due to mopping impact, time-lapse when grounding, and easy to rust will increase the leakage resistance and other shortcomings, and now the new tank trucks are equipped with rubber grounding belt. Therefore, the static grounding wire should be adjusted frequently to ensure that it has good contact with the ground and a multimeter should be used to check whether it is unobstructed, whether it is broken, and replace it if problems are found. The role of the oil separator is to reduce the sloshing and splashing of oil in the tank during the transportation of the aluminum tanker truck trailer to reduce the generation of static electricity. If the oil separator is removed from the maintenance oil tank, it should be installed in time, and it must not be regarded as an optional device.

Through the video below, you can learn about different types of fuel tanker semi trailers (like 3 axle fuel tanker, 4 axle storage tanker trailer, stainless steel tanker trailer, acid tanker trailer, fuel tanker with flatbed trailer, fuel tank Full trailer)

And the process, testing, packaging and customer feedback, etc.

Welcome to click “Technical“, you can get more article about our trailers.

Click “Product“, you can find your favorite semi trailer.