The ABS anti-lock brake system is mainly composed of the trailer ABS controller, wheel speed sensor, and ABS system power cord. Generally, ABS has four sensors. After multiple installation tests by trailer manufacturers, the sensors are installed on the front and rear axles of the three-axle flatbed trailer to achieve the best braking effect. The controller mainly controls the pneumatic system according to the signal fed back by the wheel speed sensor to achieve the purpose of anti-lock.

The ABS system is the abbreviation of Anti-Lock Braking System. It is a very important safety device on the flatbed trailer. It is used to prevent the wheels from locking and dragging when the container trailer is braking, so as to improve the directional stability, steering maneuverability and shorten the braking distance during the braking process of the high bed trailer.

The flatbed container trailer ABS anti-lock brake system can send out a sense in a timely manner to increase the friction of the 40 ft flatbed trailer to prevent loss of direction control and effectively avoid many accidents. Therefore, many 40ft trailer have installed ABS systems.

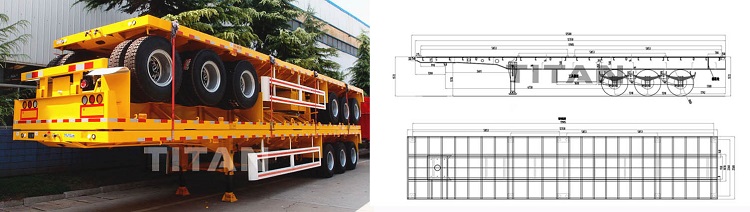

40FT Platform Container Semi-Trailer

Working principle

The flatbed semi trailer ABS anti-lock brake system first measures the speed signal of each wheel through the sensor and sends it to the controller. The controller analyzes and calculates the input signal and sends a brake to the air pressure regulator according to the movement of the wheel. The pressure control command, when it finds that a certain wheel is about to lock, immediately let the regulator discharge the brake air in an appropriate amount, reduce the friction between the brake hub and the brake shoe, and make the wheel speed rise appropriately, when the controller finds When the wheel speed rises too fast, the regulator will stop exhausting and the wheel speed will decrease. During this process, the regulator can have up to 3 to 5 control cycles per second. Through the "lock-and-release-lock-and-release" cycle, the brake pressure can be effectively controlled to overcome the deviation, side slip, and tail flicking during emergency braking, and prevent the car body from losing control. The wheel slip rate is always kept in the ideal range, so as to obtain the best braking effect.

It is a safety brake control system with the advantages of anti-skid and anti-lock. flatbed semi-trailer without an ABS system can only brake quickly when they encounter an emergency situation and have too little time to brake slowly. At this time, the wheels are easily locked, and the semi truck flatbed trailer's sprint inertia may cause dangerous conditions such as side slip, deviation, and uncontrolled direction. In new flatbed trailers equipped with ABS, when the wheel is about to reach the next deadlock point, the brake can be applied 60 to 120 times in one second, which is equivalent to non-stop braking and relaxing.

40Ft Flatbed Semi-Trailer with 3 axles

The sensor installed on the wheel sends a signal that the wheel will be locked. The controller instructs the regulator to reduce the oil pressure of the wheel brake cylinder and reduce the braking torque. After a certain period of time, the original oil pressure is restored. This continuous cycle (up to 5 to 10 times per second) always keeps the wheels in rotation and has the maximum braking torque. For high bed trailer without ABS installed, if you press the brake pedal hard while driving, the wheel speed will decrease rapidly. When the braking force exceeds the friction between the wheel and the ground, the wheel will be locked, and the completely locked wheel will make the tire The friction with the ground decreases. If the front wheels are locked, the driver cannot control the direction of the flatbed trailer. If the rear wheels are locked, the side slip phenomenon is very likely to occur.

Tip: In an emergency, the brake pedal must be pressed to the end to activate the ABS system. At this time, the brake pedal will have some jitter, and sometimes there will be some sound, but it cannot be released, which indicates that the ABS system has started.

1. Ensure that there is no air leakage or lack of air pressure in the brake air circuit of the tractor, and that the tractor has conventional braking.

2. When you maintain the wheel, you should pay attention not to damage the surface of the ring gear. If there is dust or oil on the surface of the ring gear, you need to clean the wheel speed sensor.

3. You should always check whether the sensor connector is loose. If you need to replace it, do not insert it incorrectly. Make sure that the gas path corresponds to the sensor one-to-one.

4. When you apply emergency braking on wet roads, you only need to apply full braking.

5. When installing the wheel, push the sensor to the end first to ensure the gap between the sensor and the ring gear. Be careful when installing the wheel hub, and do not install it brutally.

6. The trailer is equipped with a pipeline filter, which needs to be cleaned once every three months to ensure that the pipeline is clean to prevent damage to the ABS.

Advantage

1. Improve the stability of braking, prevent side slip, tail flick and trailer folding, etc., thus ensuring the safety of the vehicle.

2. The maneuverability of the container platform trailer's steering during braking is improved, the deviation is prevented, and the controllability of the direction during steering is ensured.

3. The braking distance can be shortened on most roads. The higher the speed of the vehicle, the more the distance is shortened (compared to the brake without ABS).

4. It can reduce the excessive wear of the tires when the wheels are locked, and reduce the use cost of the high bed trailer.

The ABS system can make full use of the maximum adhesion between the wheels and the road surface for braking, thereby increasing the braking deceleration and shortening the braking distance, but the most important thing is to ensure the directional stability of the platform trailer.

Through this video below, you can learn about different types of flatbed semi trailer,such as 2 axle,3 axle,4 axle, flatbed etc. As well as the process, testing, packaging and customer feedback, etc.

Welcome to click “Technical“, you can get more article about our trailers.

Click “Product“, you can find your favorite semi trailer.