Dangerous chemicals have the dangers of explosion, flammability, poison, corrosion and radioactivity. Once a traffic accident occurs, the harm caused is often greater. Drivers should keep their attention while driving, and need to check more while resting during driving to ensure the safety of the vehicle and the person. We sorted out the relevant points for you from the loading of hazardous chemicals, preparations before going to the road, and safe driving.

The chemical sulphuric tanker trailer is used for transporting different kinds of acids such as: sulfuric acid, hydrochloric acid, hydrofluoric acid, Nitric acid and Acetic acid among others as used for different industrial applications.

Acid Tanker Trailer produced to transport the chemical liquid with a single compartment, 5,000-gallon sulfate transportation solution.

Acids have different chemical and physical properties. In that case, different acids need different materials for the construction of their specific tanker. Chemical liquid transport semi trailer has different requirements for tank material depending on the characteristics of the medium being transported. Common chemical sulphuric tanker trailer materials are stainless steel, carbon steel, aluminum, etc.

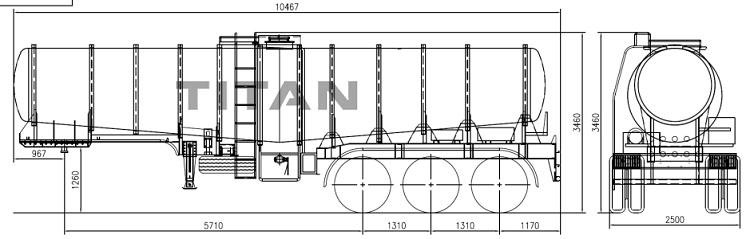

19cbm sulfuric acid tankers for sale

In addition to the selection of corrosion-resistant materials and reasonable structural design, the anti-corrosion of sulfuric acid tanks can also take some other measures, such as reducing the flow rate of sulfuric acid, electrochemical protection, passivation, using cover layer protection and strengthening and improving the operation management of storage tanks.

1) Change the flow state of sulfuric acid.

Since the corrosion resistance of carbon steel in sulfuric acid depends on a layer of ferrous sulfate protective film formed on its surface, when this layer of protective film is destroyed, its anti-corrosion ability is greatly reduced, and as a result, the corrosion rate increases sharply. In order to protect this protective film, the flow rate of sulfuric acid should be strictly limited, and the flow rate of sulfuric acid is generally strictly controlled within 50mm / s;

2) Electrochemical protection.

Mainly the anode protection method. After the anode protection is applied, the corrosion rate of carbon steel in sulfuric acid is greatly reduced;

3) Use of thermal insulation coatings.

Since the corrosiveness of sulfuric acid increases with the increase of temperature, in order to avoid the temperature of sulfuric acid in the tank due to sunlight, the outer wall of the tank should be sprayed with a light-colored (usually white) topcoat, or use Very popular heat-shielding paint on the surface;

4) Strengthen management.

Concentrated sulfuric acid has strong hygroscopicity. When carbon steel sulfuric acid storage tanks are often filled with concentrated sulfuric acid, the corrosion is very weak, but if they are often emptied (such as frequent parking, not used for a long time after emptying), the thin attached to the inner wall of carbon steel tank A thin layer of concentrated sulfuric acid will quickly absorb water in the air and become thinner, and the corrosion of carbon steel becomes so severe that it causes perforation. It is also necessary to strengthen the management of the venting of concentrated carbon sulphate steel tanks, shorten the venting time, or take other management measures such as dehumidification.

3 axle chemical tanker trailer specification

3 axle chemical tanker trailer specification

1. Dangerous chemical transportation enterprises, vehicles, escorts, and loaders must obtain corresponding qualifications.

2. The loading medium is consistent with the tank spraying medium and the vehicle road transport certificate.

3. The loading of dangerous chemicals is even and balanced, and the whole is fixed, so that one vehicle and one cargo can be mixed. Different dangerous chemicals cannot be mixed and overloaded.

4. After loading the hazardous chemicals, the name, shape, quantity, disposal method, and contact information of the hazardous chemicals shall be recorded in writing and carried along with the vehicle.

5. After loading the liquid hazardous chemical tanker, the emergency shut-off valve should be closed to ensure no damage or leakage.

Inspection work before driving

1. The acid tanker trailer number plate is installed intact, the safety inspection signs and insurance signs are placed correctly, the driving license, road transportation license, and road transportation permit for highly toxic chemicals are complete and valid and can be carried with the vehicle.

2. Safety devices such as vehicle marking lights, signs, reflective signs, side rear protective devices, and fire extinguishers are well configured, and satellite positioning devices are working properly.

3. The vehicle braking, lighting, and turn signal safety systems meet the operating requirements, the tire specifications are qualified, the wear is normal, and the retreaded tires are not used.

4. The emergency cut-off device for the transportation of liquid hazardous chemicals tankers is in good condition and is in a closed state.

TITAN fuel tanker trucks for sale

TITAN fuel tanker trucks for sale

Safe driving

1. Choose a reasonable driving route with good traffic conditions, stay away from towns and residential areas, and do not enter the prohibited areas of dangerous goods transport vehicles. Vehicles transporting highly toxic chemicals must be driven according to the time and route approved by the public security organs, and may not be changed at will.

2. Maintain a safe driving speed. In any case, the driving speed should not exceed 80km / h. At night, under low visibility conditions such as rain, fog, snow and snow, you must drive at a reduced speed.

3. Maintain a reasonable driving distance from the vehicle in front, and increase the separation distance in case of rain, fog, snow and other bad weather.

4. It is not allowed to change lanes arbitrarily while driving. Highway traffic must be driven in the specified lanes.

5. Drivers should keep their attention. They should stop and rest every 2 hours or so, and check the technical status of the vehicle in time to ensure that the emergency shut-off valve is closed.

Through the video below, you can learn about different types of fuel tanker semi trailers (like 3 axle fuel tanker, 4 axle storage tanker trailer, stainless steel tanker trailer, acid tanker trailer, fuel tanker with flatbed trailer, fuel tank Full trailer)

And the process, testing, packaging and customer feedback, etc.