The high temperature in summer is approaching, and safety is the first priority for the flatbed trailer driver! Only after checking all the problems before driving, can you go on the road. Based on the needs of truck friends, we now summarize the summer semi-trailer maintenance strategy for the reference of trailer friends:

Check the tire pressure to make sure that there is no lack of air or debris, and then see if the steel ring is deformed or cracked.

Before leaving the vehicle, the tire pressure should be properly reduced. When resting during driving, check the tire temperature and pressure in time. If tire temperature and tire pressure are found to be too high, do not deflate or pour cold water. Instead, choose a cool place to stop and let the tire cool naturally.

Don't think that the detail of tightening screws is troublesome, you should check whether each screw is tightened one by one. It is a small matter to lose the screw halfway, and the money can be solved if the high bed trailer tire is lost. To use a sentence is "there is no trivial matter in tires".

When entering the high-temperature season, pay attention to changing the specific gravity of the electrolyte, which is smaller than that in winter.

At the same time, it is necessary to regularly check the battery liquid level, add distilled water in time, and keep the vents open.

In order to prevent excessive consumption of electrolyte due to high temperature, it is necessary to adjust the generator regulator to reduce the generator charging airflow.

According to the compression ratio of the engine, gasoline with an appropriate octane number is selected.

Attention should be paid to maintaining the normal temperature of the engine, appropriately delaying ignition and enriching the mixture in advance. At the same time, the carbon deposits in the combustion chamber, valve head and other parts should be thoroughly removed in time.

In addition, the flatbed semi trailer should choose a suitable speed before going uphill again. Maintaining good power, preventing the vehicle speed from being too fast or making the mixed gas slightly lean, can effectively prevent the occurrence of deflagration.

Clean the gasoline filter, fuel tank and oil pipeline to keep it clean and smooth.

Check and adjust the working pressure of the gasoline pump to keep it normal. Once the air resistance appears, it should stop to cool down, disassemble the carburetor inlet pipe joint, pull the gasoline pump hand rocker to make the gasoline fill the oil pipe, and restore the normal fuel supply.

In order to prevent the gas supply system from generating air resistance, a cold compress is usually used to reduce the temperature and make the oil supply smooth. Insulation pads can also be added, asbestos plate gaskets are added between the cylinder and the gasoline pump to reduce the heat transferred from the engine to the gasoline pump and prevent air resistance. In addition, the use of electric gasoline pumps is an effective way to prevent air resistance.

We must turn on the watering system at any time to keep the semi-trailer tires at a constant temperature to reduce the temperature of the tires during high-speed braking when braking, so we often see that many semi-trailers have a lot of water vapor during braking.

(1) Waxing. The acidic components in the rain water have strong corrosion of automotive coatings. Therefore, it is best to protect the logistics trailer surface in summer.

(2) Anti-rust of the chassis. In addition to paint removal, the chassis is close to the ground and is subject to corrosion, so we must pay attention to the cleaning and anti-rust treatment of vehicle chassis.

(3) Disinfect the trailer. Clean the interior of the vehicle during the rainy season to avoid the harm of various bacteria to the human body.

(4) Check the circuit in time. During the rainy season, the flatbed trailer electrical system should be checked frequently to avoid leakage failures.

(5) Heat regularly. Turn on the heater to roast mold inside. When the sun is out, you can stop the sun from being exposed to the sun and open the windows to allow the air to convict.

(6) Check the platform trailer cooling system parts to ensure complete and intact.

Mainly check the sealing of the cooling system, the tightness of the fan belt, whether the vents and vents on the radiator cover are smooth, whether the cooling water is sufficient, and whether the thermostat is in good condition. In addition, the scale should be eliminated in time, and the engine cooling water should use soft water or treated hard water as much as possible.

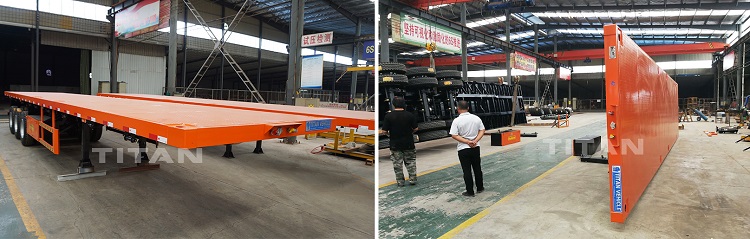

Through this video below, you can learn about different types of flatbed semi trailer, such as 2 axle, 3 axle, 4 axles, flatbed etc.

As well as the process, testing, packaging and customer feedback, etc.

Welcome to click “Technical“, you can get more article about our trailers.

Click “Product“, you can find your favorite semi trailer.